Friction

Overview

Friction in fluid flow refers to the resistance encountered as fluid moves through pipes, ducts, and equipment. This resistance manifests as pressure drop, which must be overcome by pumps or compressors to maintain flow. Understanding and accurately predicting friction is essential for designing efficient piping systems, sizing pumps and compressors, and minimizing energy consumption in industrial processes ranging from water distribution networks to petrochemical plants.

The fundamental relationship governing friction in pipe flow is the Darcy-Weisbach equation, which relates pressure drop to the Darcy friction factor (a dimensionless parameter also called the Moody friction factor). This friction factor characterizes the energy dissipation per unit length of pipe and depends primarily on two factors: the Reynolds number (which indicates whether flow is laminar or turbulent) and the relative roughness of the pipe wall (the ratio of surface roughness height to pipe diameter, ε/D).

Flow Regimes and the Friction Factor: In laminar flow (Re < 2300), viscous forces dominate and the friction factor follows the simple analytical relationship f = 64/Re. The FRICTION_LAMINAR tool implements this exact solution. As Reynolds number increases beyond Re ≈ 2300, flow enters a transitional regime where it fluctuates between laminar and turbulent states before becoming fully turbulent around Re ≈ 4000. In turbulent flow, the friction factor depends on both Reynolds number and relative roughness, requiring more complex correlations.

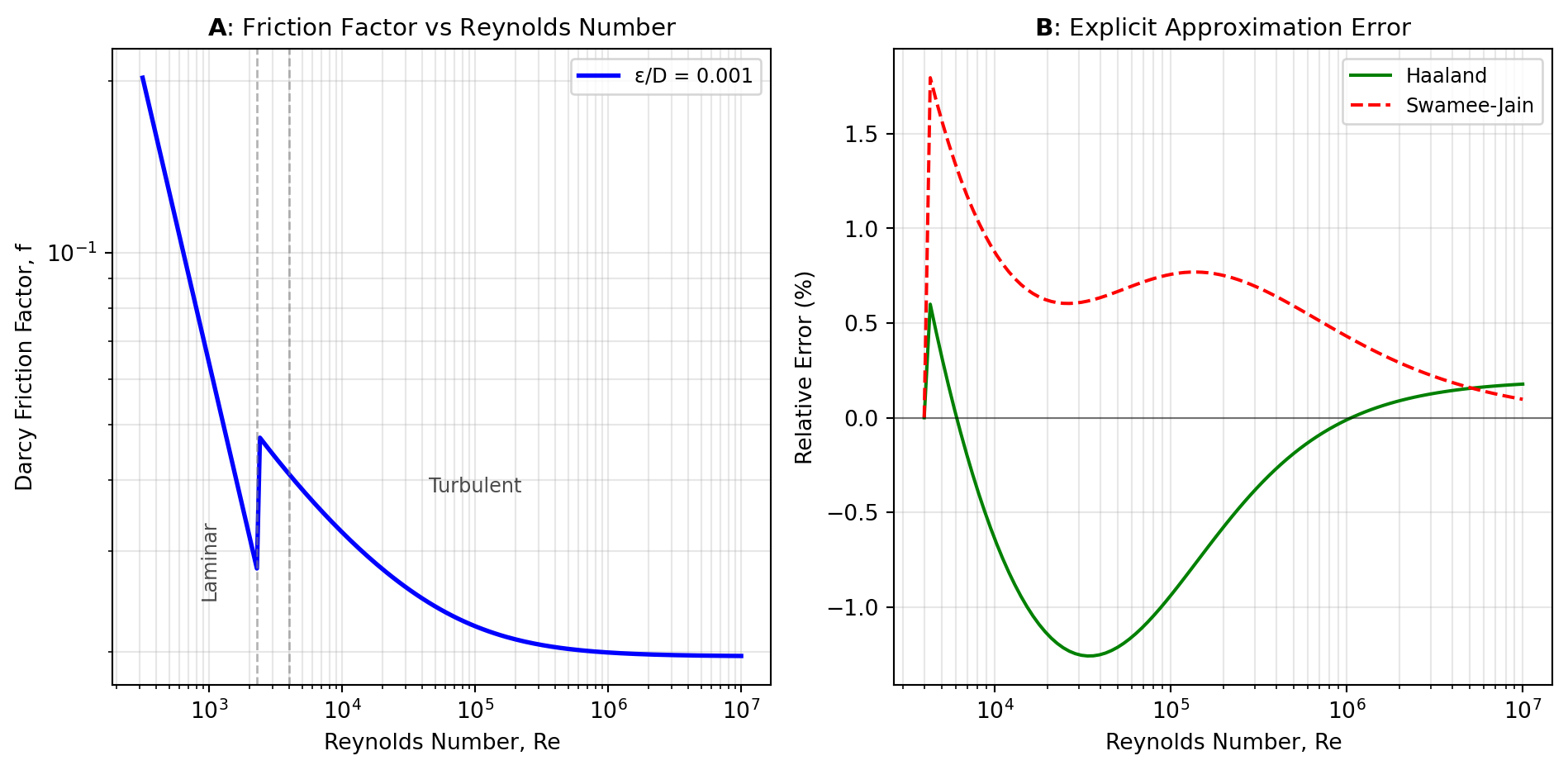

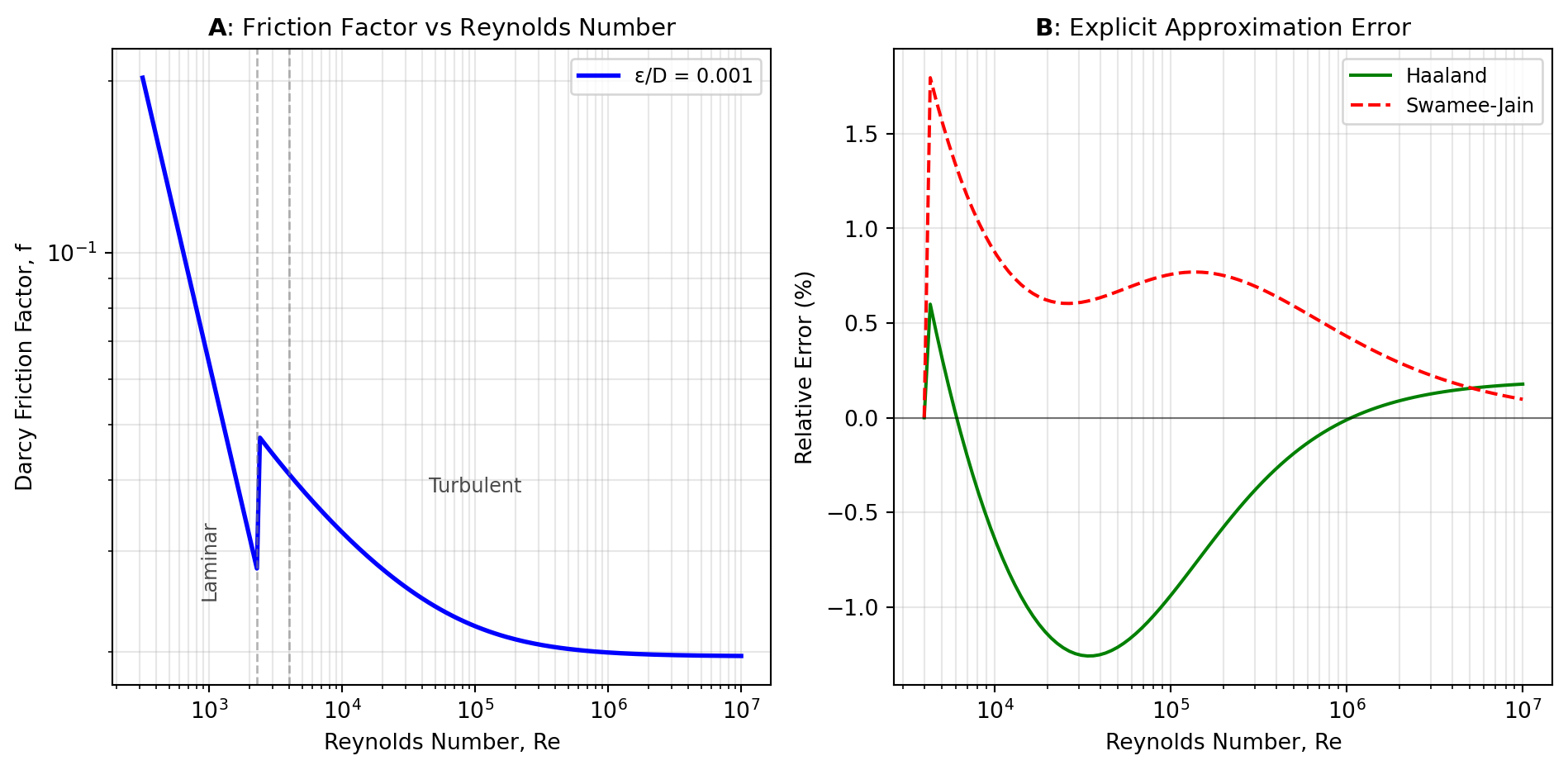

The Colebrook Equation: For turbulent flow in rough pipes, the implicit Colebrook equation is considered the reference standard. However, because it requires iterative solution, numerous explicit approximations have been developed for engineering calculations. The COLEBROOK tool provides the exact iterative solution, while HAALAND, SWAMEE_JAIN, and MOODY offer explicit approximations with varying accuracy and computational simplicity. For high-precision applications, CLAMOND provides a solution accurate to nearly machine precision. The figure below (Figure 1) illustrates how friction factor varies with Reynolds number and compares the relative error of common explicit approximations.

Specialized Correlations: Different flow geometries and conditions require specialized treatments. The BLASIUS correlation applies specifically to turbulent flow in smooth pipes (where roughness effects are negligible). The CHURCHILL equation provides a universal formulation valid across all flow regimes, from laminar through transitional to fully turbulent, making it useful when flow regime is uncertain. For curved pipes and helical coils, secondary flow effects alter the friction characteristics; FF_CURVED and HELICAL_RE_CRIT handle these geometries. Plate heat exchangers with chevron-style corrugations have unique friction characteristics addressed by FP_MARTIN and FP_MULEY_MANGLIK.

Practical Pressure Drop Calculations: The friction factor is typically used to calculate actual pressure drop in piping systems. ONE_PHASE_DP applies the Darcy-Weisbach equation to compute frictional pressure loss, while DP_GRAV calculates the gravitational component for inclined pipes. For fully turbulent flow in commercial pipe, FT_CRANE implements the simplified Crane correlation. The VON_KARMAN equation provides the limiting friction factor for rough pipes at infinite Reynolds number. For compressible gas flow in pipelines, the TRANS_FACTOR tool converts between Darcy friction factor and transmission factor.

Selecting the Right Tool: For routine calculations with moderate accuracy requirements (±5%), use FRICTION_FACTOR, which automatically selects appropriate correlations based on flow regime and roughness. For high-accuracy applications requiring precision better than 1%, use CLAMOND or COLEBROOK. When flow regime spans laminar to turbulent ranges, CHURCHILL provides continuous coverage. For specialized geometries like helical coils or plate heat exchangers, use the geometry-specific correlations.

All tools in this category are implemented using NumPy and SciPy for numerical computations, with many correlations drawn from established references like Crane Technical Paper 410 and Perry’s Chemical Engineers’ Handbook.

Tools

| Tool | Description |

|---|---|

| BLASIUS | Calculates Darcy friction factor for turbulent flow in smooth pipes using the Blasius correlation. |

| CHURCHILL | Calculate Darcy friction factor using the Churchill (1977) universal equation for all flow regimes. |

| CLAMOND | Calculate Darcy friction factor using Clamond’s high-precision solution accurate to nearly machine precision. |

| COLEBROOK | Calculate Darcy friction factor using exact solution to the Colebrook equation. |

| DP_GRAV | Calculate gravitational pressure drop component for single-phase flow in inclined pipes. |

| FF_CURVED | Calculate friction factor for fluid flowing in a curved pipe or helical coil, supporting both laminar and turbulent regimes. |

| FP_MARTIN | Calculate Darcy friction factor for single-phase flow in Chevron-style plate heat exchangers using Martin (1999) correlation. |

| FP_MULEY_MANGLIK | Calculate Darcy friction factor for single-phase flow in Chevron-style plate heat exchangers using Muley-Manglik correlation. |

| FRICTION_FACTOR | Calculate the Darcy friction factor for fluid flow in a pipe using various correlations, automatically selecting appropriate method based on Reynolds number and relative roughness. |

| FRICTION_LAMINAR | Calculate the Darcy friction factor for laminar flow using the theoretical solution fd = 64/Re. |

| FT_CRANE | Calculate the Crane fully turbulent Darcy friction factor for flow in commercial pipe. |

| HAALAND | Calculate Darcy friction factor using the Haaland (1983) approximation. |

| HELICAL_RE_CRIT | Calculate the transition Reynolds number for fluid flowing in a curved or helical pipe between laminar and turbulent flow. |

| MOODY | Calculate Darcy friction factor using the Moody (1947) correlation. |

| ONE_PHASE_DP | Calculate single-phase pressure drop in a pipe using the Darcy-Weisbach equation. |

| SWAMEE_JAIN | Calculate Darcy friction factor using the Swamee-Jain (1976) equation. |

| TRANS_FACTOR | Convert between Darcy friction factor and transmission factor for compressible gas pipeline flow. |

| VON_KARMAN | Calculate Darcy friction factor for rough pipes at infinite Reynolds number from the von Karman equation. |